Product Description:

In the physical inspection and chemical analysis of grain quality, such as the analysis and inspection of grain viscosity and nutritional components, the measured samples must be crushed.

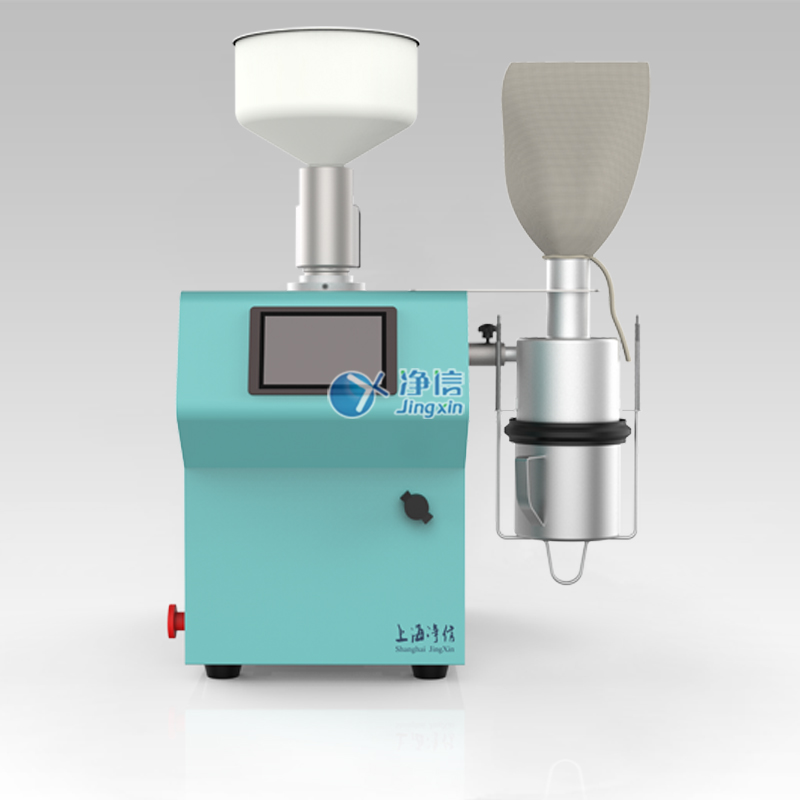

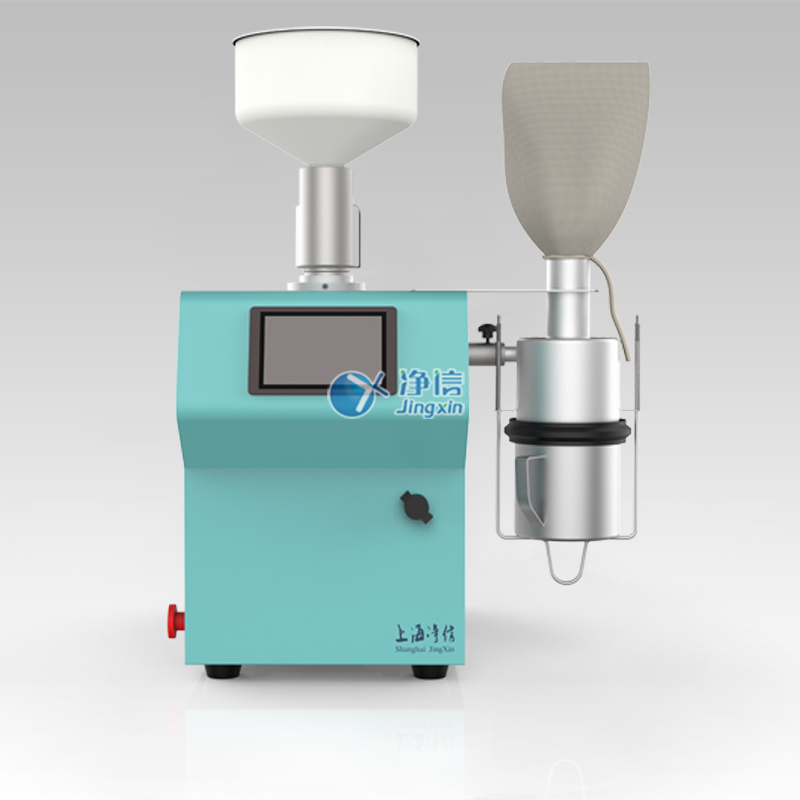

The hammer-type cyclone mill is a kind of crushing equipment with beautiful appearance, compact structure, easy operation, stable operation and durable. This equipment is mainly suitable for the crushing of samples of small and medium grains (water content conforming to national standards) such as wheat and rice in the grain industry. The samples crushed by this machine (samples passing through sieve plates with different apertures) are suitable for the determination of the quantity and quality of gluten, the sample preparation and the measurement and analysis of other fineness requirements such as falling number, near-infrared composition, grain viscosity, etc.

Performance characteristics:

1. Using high-speed grinding and hammering, the sample becomes powder, and the high-speed airflow passes through the stainless steel sieve into the stainless steel integrator to make the required uniform sample;

2. There are excellent sound-absorbing and sound-proof materials in the box, with low noise;

3. The motor has a built-in temperature control protection circuit, once the motor exceeds the set temperature, it will automatically stop;

4. When the sample is crushed, it has the function of high-speed airflow to automatically clean the grinding chamber, and there is no need to stop work for manual cleaning when the sample is crushed;

5. Irregularly shaped large grain samples (such as large grain corn), etc., are fed and crushed;

6. The high-speed airflow during the hammering crushing process will cause the loss of water in the sample. Due to the temperature control limitation, the temperature in the cavity is kept at room temperature. The new type of cyclone mill can minimize the water loss. Generally, the moisture content is 10-20%. Samples will lose 2-5% of water during the crushing process.

7. LCD touch operation, clean interface and easy operation. Temperature control, crushing time, main motor speed, and cutting speed can be set.

Technical parameter:

Main parameters | Parameter range |

voltage: | AC220±10V 50Hz |

power: | 800W |

Working room diameter: | 110mm |

Rotating speed of grinding hammer: | 16800r/min——23800r/min (adjustable) |

Temperature in the cavity: | Temperature control device in the machine cavity 30-50 samples can be crushed continuously, and the temperature in the cavity generally does not exceed 48℃ |

Cutting speed: | Cutting speed: adjustable from 1-9 |

Sieve plate aperture: | The aperture size is 0.5 0.8 1.5mm (high hardness stainless steel sheet 0.8 thickness), which is relatively more durable and durable than the replacement of the old cyclone mill sieve |

Touch interface | LCD touch interface |